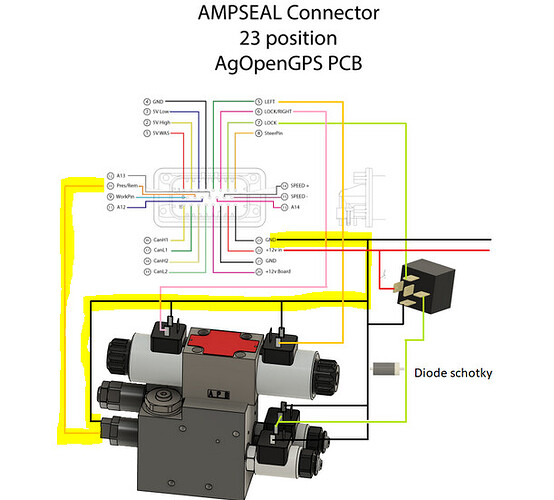

Is i correct if i read its something wrong whit this wiring?

The pressure sensor does not get any voltage input on @baraki 's valve?

What voltage shoud i feed it with? 5V or 12V?

None of those.

You need to use remote, so connect 1 and 2.

That way the pressure switch on baraki valve connect the 5 V (at the optocoupler at top of your picture) to GND

Unless you have changed the pressure switch to another presure sensor?

No. That explain how it shoud be connected

If there are more than 5V coming from the AWS to v4.1 Micro, are they simply ignored, or does the board die?

Hello, I’m a new noobie here, with a 4.1 std board. I am in the “bench testing phase” with all my components, I have now put everything together, following the wiki. I was quite surprised that it seems to be working, and I havent let out any magic smoke yet.

But I have two questions at this stage (probably more to come…):

1: The LED for GPS/RTK stays RED even though I am connected to Ntrip, and AOG says RTK fix. The F9P board blue LEDs are OFF for NO RTK and GPS FIX is blinking.

Is something wrong here? RTK seems to be connected and working but no green LED?

2: The LED for AS/ACT also stays red, but should this go green when stationary, in bench testing? I tried going to simulator mode but AOG says no simulator when GPS connected. Can autosteer be tested in simulator mode? (I am using cytron to steer with motor, works when using manual buttons in AOG). And do I have to remove the F9P board from the AIO board to get to simulator mode?

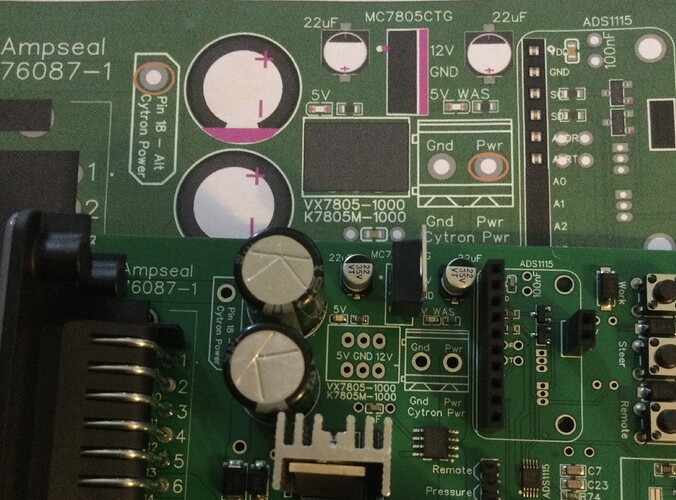

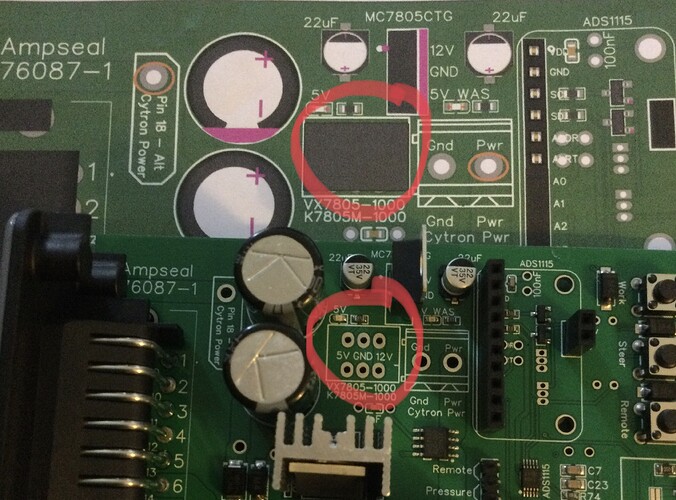

Just trying to get my AIO board working and found I had no power on 5v.

Looks like something missing on the board,any info on this part please.

The light for the autosteer will only go green when your moving, to get it to go green when stationery and to test your motor press the pwm button in the steer setup menu and you can use the arrows to test your motor .

Should’ve need to remove anything from the board to enable simulator mode

Looks like you have the capacitors missing. There is always a place to install these yourself via through hole components so look underneath the board for where they go, there not always next to where the surface mounted option is.

Just had another look and your missing alot of components, is this a blank pcb or a jlc assembled board

What is involved in using the canbus chip on a v4 board to read a factory fitted wheel angle sensor?

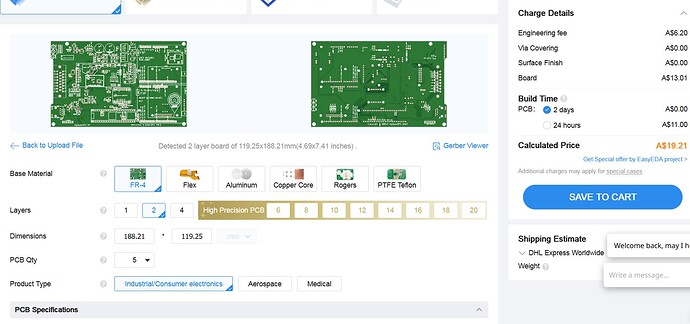

Hi! I composed an order with jlcpcb for the micro v4.1 pcb and luckily all the components are available! I am going ahead and place the order. Can you assist me with a list of other items needed to make the pcb fully functional. I mean the accompanying bill of materials in the zip file you made available is for components on the pcb itself. Its not the complete bill of materials to make the board fully functional? Can I ask your indulgence and point me to the rest of the bill of materials to make the board fully operational (excluding external components of course) and including preferred sources. Really appreciate the assistance. Thanks.

Needs custom code - at the moment, there are two version; CANBUS (where steering and wheel angle arrive over same) and “traditional” (where WAS and motor driving are analog).

I’ve a hybrid version where a traditional 5V WAS is used, and CANBUS is used to drive the Keya motor, but you need the other way round. It’s on the to-do list that you’ll be able to pick whichever way you want to go from a single code base tho.

Hi,

at first: the AIO v4.1 standard is great.

However I have few minor points to discuss for improvements:

-

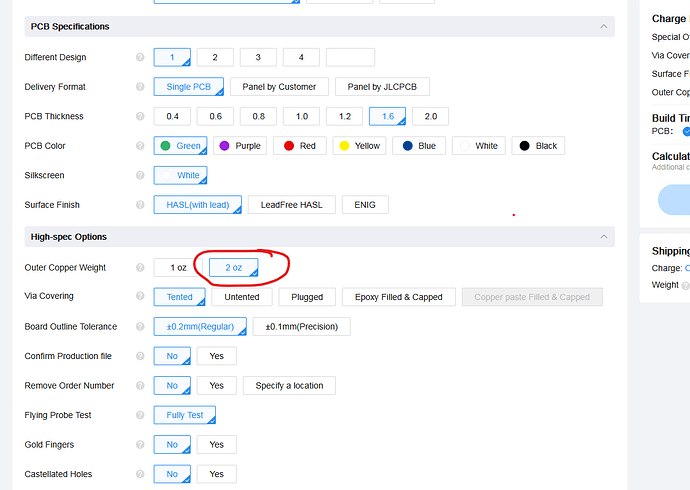

(more a tip:) If you order the PCB at JCPCB select (Outer Copper Weight = 2 oz)

Thicker copper means less heat, especally for the high current traces -

The routing of the WAS_H trace is dangerous!

The trace passes very close the motor driver output of the Cyton, which switches high currents (with low transient time = lot of high frequency components in the spectrum) which can incluence the quality of the WAS signal. From electromagnetic complience point of view, the cyton and the ADC should be as good separated from each other as possible. -

2-layer platine makes the design cheap, but is the most difficult to design. The problem here is that the the trances and the coresponding ground currents can not flow as close as possible to each other, since the gound plane is interrupted. A four layer PCB can be created more easy

-

for a better Ground potential at TOP and BOTTOM there should be much more vias connecting the ground area fills of both sides.

-

I don’t understand the function of R53 and C30. The inputs of the ADC are already high impedant. And for a low pass filter the order is wrong.

-

Further I would like to have an 12V-to-24V boost converter already included in the PCB. It’s not black magic. The from electromagnetic complience point of few it is less critical than the Cyton motor driver.

-

The mounting holes of the ADS1115 are smaller than all others. An M3 screw does not fit.

-

Next to all mounting holes there should be no traces (except ground). So it is possible to use screws directly without isolation rings. The coating of the PCB usally isiolates at first, but with time I creates a short due to the high vibrations. A ground protection ring with 1 mm or so around each monting hole would relaxe the problem.

This points shall just help to improve the great projekt and shall not be understood as critics.

Happy discussion!

I have now moved the jumper over to the remote side. I am now always have signal on remote. It does not matter if the autosteer is enabled or not. It does not matter if i’am moving / trying to move the steering wheel.

Some more tips?

How many counts have you ser remote off to?

Also measure that the pressure swit4change state, when you turn steering wheel, and make high pressure

It light up the led on the board, I have tried set it on 1 and 3.

How can i measure the pressure?

Adjust the screw at end of sensor.

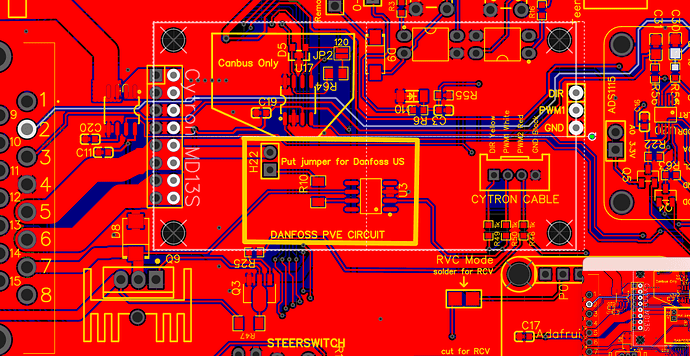

Cytron Mod on V4 micro:

Team does the freewheel mod still work the same? Remove the 2 components (diode and resistor) and solder NC to the resistor pad. Does the other side of NC need to be connected to PWM2 on the Agopengps pcb ?