Ok.

3160 must be connect to A2 or A0 ?

(for AOG 5.2 and pcb v2)

Did you check with engine running?

Wire 5200 on 716-11 is my constant 12 V

I can´t help you with the 3185/3187 problem as it does not seem to be same diagram as I have,

(on mine 3185 stay at 0 volt because it does not have any pin at the back of column autosteer switch, and 3187 get 12/13 V when autosteer switch at column is on)

I do NOT have the button at armrest, like you and fivefinnishfarmer have.

It is A0 on PCB (arduino A0) for 3160

The other wires you also have correct.

In the Manual.pdf around page 14, you see where to set psi for pressure cut off.

Did you find this thread ? Case IH Puma 230, autosteer ready - #12 by CVX

Ok. Many thanks! ![]()

I will try to connect.

I will put a relay for 3168 with pwm2. It is ok?

I see your thread ![]()

Yes a relay with a 5v coil, and feed 12v to 3168 ![]()

For 3168, i have to cut or i have to make a Y?

Not a Y. Cut or I believe fivefinnishfarmers took it out of the connector (See his pictures)

Ok. ![]()

Hello larsvest, could you please make some photos of hydraulic valves and connections? I don´t have steer ready tractor and I am going to make electric-hydraulic steering. Just want to know how it looks original from NH (connection of hoses and so) and maybe type of electric-valves if you can find out. thanks a lot…

@David A picture can´t really show, the piping is hidden, the valve block is mounted on top of engine, and not easy to access. But here is a link you can explore: (T6.175) - TRACTOR - TIER 4B (3/15-) (41.432.AE[01]) - VAR - 743812 - AUTOGUIDANCE, VALVE New Holland Agriculture

Or this (click on a variant at bottom on the first page)(T6.175) - TRACTOR - TIER 4B (3/15-) (41.432.AC) - VAR - 391610, 718228, 718230, 743812, 758479, 758480, 758481 - AUTOGUIDANCE, VALVE, LINE New Holland Agriculture

But it is actually the same components as what you find in the fluidsystem valve you also can find on this forum.

It is really just a (6/2 like) valve, with 12V solenoid to activate (called Dump valve in CNH language) a pressure sensor (with output 0 to 5 V) and a proportional valve with two 12 V solenoids.

You should also search for proportional valve. And check the other success stories, to see how to build a autosteer system with proportional valve.

Larsvest.

Hi.

I am ready to connect my pcb.

For pressure sensor, how much bar?

Many thanks.

The lowest you can go, i think its 1. Works the best.

Fastest Reaction, but not to crazy.

Hi Lars, what settings are you running for the hydraulics? I’m in setup stage with a similar machine and can’t really get a good mix of settings yet.

For the t6 and AOG version 4 the latest they have used in Gain are: prop. gain 35, Min pwm drive 44, High max 250, low max 37.

In steer the settings are: Wheel Zero 127, Counts pr degree 84, Max angle in degree 24, sidehill 0.

Pure P: Look ahead seconds 6, offline multiplier 2,8, Min look ahead in meters 4,4, U-turn multiplier 0,4

I am supposed to update to ver 5 for them, before spring. (must also change pressure input to A0 on nano)

Very interesting, I haven’t tried the prop gain down that low yet, that could be the key. On V5 I don’t think there’s an option for look ahead seconds, at least not in the PP menu.

On your Was did you get better results with the single or differential setting?

Only tried single, I do not see that was reading flicker.

I have it on single as well, tried differential but the readings were way off, only curious as to what you found. Thanks.

Is it possible for you to re-host your photos please?

They are all in the onedrive link. But you should definitely go for the fivefinnishfarmers way of doing this. He did it better.

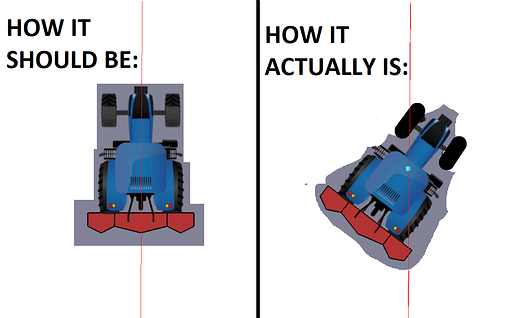

Hey larsvest, I have question. I use BNO08x any I have problem with heading. Everything else seems working good but heading is working weirdly when I turn. When I go straight error between fix2fix and IMU is about 1° but when I start turning, firstly IMU heading acts slowly and when I finish 180° turn with tractor heading keeps turning so when I go straight after turn IMU heading thinks I´m still turning and the error rise for a while about 5°. So the result is that tractor goes straight but agopengps thinks tractor is heading little bit to the side.

I have only one Arduino on which is everything connected via one USB. Can you help please? Thanks.

How it looks after 180° turn when going forward:

You are right, that is how it works normally.

But some people have been working on a solution.

I think you then need a teensy!